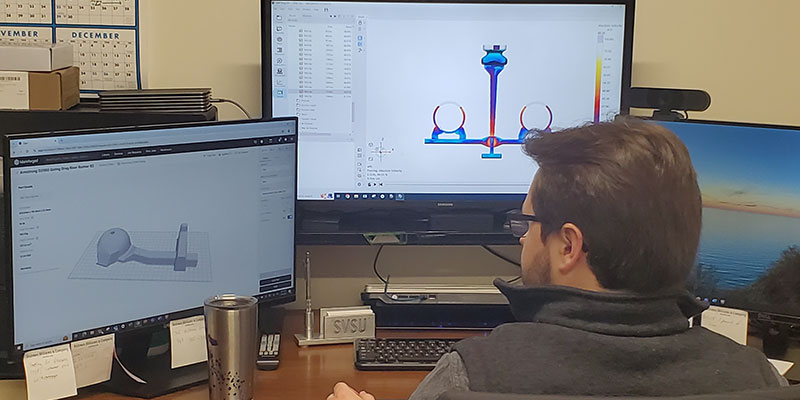

Dimensional Layout & Design Services

Great Lakes Castings can provide a PPAP submission utilizing a CMM or a scan overlay of the casting and customer supplied CAD Model.

DIMENSIONAL LAYOUT

Accurate Measurements for Consistent Quality

We understand that dimensional integrity directly affects part performance and longevity. Our comprehensive dimensional layout process includes:

Precision Measuring Equipment: Using tools like CMMs (Coordinate Measuring Machines) and digital scanners to capture exact geometries.

Tight Tolerance Validation: Conducting thorough inspections to verify all critical dimensions before moving into full-scale production.

Ongoing Quality Checks: Tracking and analyzing measurement data throughout the project lifecycle to ensure consistent casting quality.

Streamlined Design for Optimal Castability

Our design specialists and tooling experts collaborate on every project to ensure molds and cores align with best practices for gray and ductile iron. By integrating dimensional layout early in the process, we:

Optimize Gating & Risering: Improve metal flow and reduce scrap or rework.

Prevent Common Defects: Mitigate issues such as shrinkage, porosity, and mismatched parting lines.

Enhance Production Efficiency: Reduce lead times and costs by detecting and addressing design challenges upfront.

Seemless Integration with Casting & Tooling

Our dimensional layout and design services align seamlessly with precision casting, tooling design, and pattern making. This holistic approach empowers you to:

Accelerate Go-to-Market: Avoid bottlenecks by resolving design and dimensional issues early.

Improve Mechanical Properties: Confidently produce castings that meet exact functional and performance criteria.

Reduce Overall Costs: Detect minor variations before they become major production setbacks.

Ready to Ensure Spot-On Accuracy for your castings?

Contact Great Lakes Castings or request a quote today to learn how our dimensional layout and design services can enhance your gray and ductile iron projects.